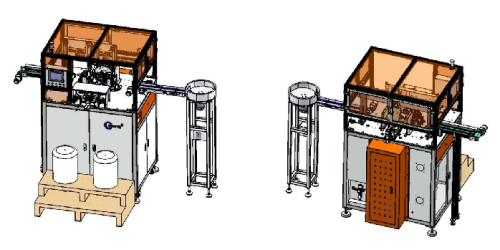

XT-CHHD002 Automatic Toroidal coil butterfly-type (Cross-winding method)winding machines with PLC control forsimplified operation.

A fully automatic magnetic ring winding machine specially designed for the symmetrical butterfly winding method of magnetic rings.

It is a two-axis machine with unmanned operation from uppering the magnetic core, feeding the wire, hooking the wire, and unloading the material. The single axis is wound on one side, which greatly improves the efficiency. The hooking time is reduced, single layer, two-layer reciprocating, and three-layer wiring can be arranged. The wiring is precise, high-efficiency, labor-saving, and has a wide range of wire diameters. The last magnetic core can run for more than 2 hours, and the entire copper wire shaft is loaded. , one person can watch multiple units. It will automatically stop when there is a shortage of materials (magnetic core, copper wire). The magnetic core can be made of amorphous, iron powder core, iron, silicon, aluminum, etc. The wire can use copper wire, or aluminum wire, and the speed is adjustable. , changing specifications is quick and easy

Product Features

A fully automatic magnetic ring winding machine specially designed for the s butterfly-type winding method of magnetic rings.

Automatic magnetic core uploading, wire feeding, winding, unloading, etc.

Dual working station design, which greatly improves the winding speed.

It can be a single layer, two layers reciprocating, three layers of wiring, precise wiring, and high efficiency.

wide range of wire diameter compatibility from 0.4mm- 1.8mm

Fully automated, One person can operate multiple machines.

It will automatically stop when there is a shortage of materials (magnetic core, copper wire).

The magnetic core can be amorphous, iron powder core, iron-silicon-aluminum, and other materials.

The wire can use copper wire and aluminum wire,

the speed is adjustable, and the specifications are easy to change Fast.

Product parameters

| Model number: | XT-CHHD002 |

| Wire Diameter : | 0.4 ~ 1.8mm |

| Coil outer diameter | 13-50mm |

| Coil Inner diameter | >8 mm |

| Wire length | 100-2800mm |

| speed | 0.6-1.5s/turn |

| working station: | 2 stations |

| Power: | 4.5KW |

| Power supply: | AC 380V,50/60Hz |

| Air pressure: | > 0.6Mpa |

| Machine dimension: | 1630*1980*2050mm |

| G. W: | 750KGS |

Hot it works

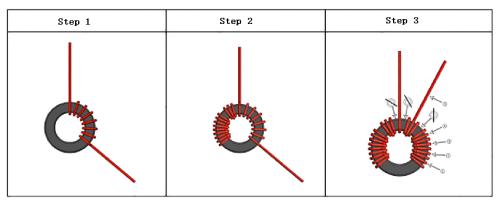

1. The magnetic core is placed on the conveyor belt. The conveyor belt runs in one direction and continuously sends the magnetic core into the diversion trough. The sensor detects that the magnetic core is in place and the conveyor belt stops. After the loading clamp clamps the magnetic core, the conveyor belt starts again. , cycle in sequence. Taking T30 magnetic cores as an example, a conveyor belt can carry about 200 magnetic cores, which can run the equipment for 1.5 hours. The equipment will automatically stop running when the conveyor belt is empty. To replace the product, you can adjust the slots on both sides.

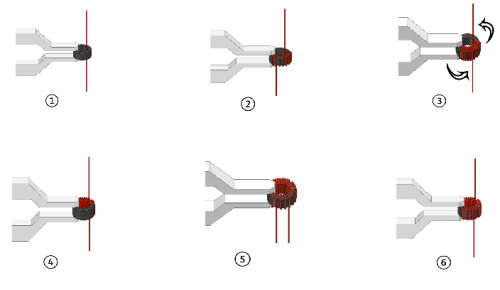

2. The upper core structure is a three-axis linkage combination. The upper core, the coil wound on one side is transferred, and the three sets of unloading are integrated into one. The core clamp is clamped on both sides to ensure that the force on both sides is even and the core will not be broken.