Fully automatic sweeping robot motor production solution

Equipment Overview

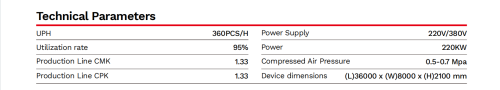

This is a highly automated, process-covered production line designed specifically for sweeping robot motor

focusing on precision manufacturing and strict quality control. The production line integrates core tasks such as winding, pressing,

welding, testing, and assembly, and is suitable for the production and processing of motors, sweeping robot motor。automotive wiper motors, automotive column motors,

automotive backrest adjustments, and medical equipment backrest drives.

Main Process:

Rotor Section: Iron Core Commutator – Winding – Spot Welding Comprehensive Test – Wire Wrap Shaping – Rotor Pressure Sensitivity Welding

– Rotor Cleaning – Rotor Baking – Rotor Turning – Rotor Balancing – Rotor Visual Inspection

Assembly Section: Rotor Pressure Sensitivity Test – Rotor Insertion – Rotor Insertion into Housing – Motor Assembly –

Magnetic Ring Installation – Motor Sealing – Motor Primary Test – Shaft Extension Measurement, Clearance, Oiling Laser Marking –

Motor Secondary Test – Low-Loudspeaker Test – Terminal Bending – Windshield Installation – Visual Inspection, QR Code Application – Motor Packaging